3D bioprinting greatly supports medicine and research. In this regard, great progress is being made in laboratories around the world. Research in this field is also conducted in the Laboratory of 3D Bioprinting and Biomaterials Research at the Institute of Materials Science and Engineering (Faculty of Mechanical Engineering at Lodz University of Technology).

3D printing or additive manufacturing is a process of producing three-dimensional solid objects from a digital file. Their production is done by additive processes by applying successive layers of material until the object is complete. Each of these layers can be viewed as a thinly sliced horizontal cross-section of the eventual object.

In 1984, Chuck Hull developed the technology of printing three-dimensional objects from digital data - this year is considered the beginning of the additive manufacturing industry. 1999 marks the beginning of 3D bioprinting - scientists at the Wake Forest Institute of Regenerative Medicine used a 3D printer and produced a synthetic bladder-shaped scaffold that was populated with cells taken from the patient.

Since then, tremendous progress has been made in both 3D printing and bioprinting. The printing techniques available today enable the production of very small and large objects of complex shapes with very high accuracy and speed from a wide range of polymers, metals, glass, sand, clay and various other materials and their composites.

Additive techniques are increasingly used in medicine, including the production of surgical gauges and anatomical models of healthy and damaged organs and tissues. Preoperative imaging of the tumour, thanks to the printed model, can allow the doctor to better plan and prepare the surgery to remove the tumour. They can also serve as a kind of intraoperative guide. Anatomical models allow young doctors to learn how to operate on physiological and pathological forms of organs without having to work on a cadaver. Thanks to 3D printing, all educational and demonstration models can be provided quickly and, most importantly, inexpensively. In addition, medical devices (prostheses, wearable devices) are already being manufactured using 3D printing techniques. In such applications, polymers (in the form of thermoplastic filaments, granules or sintered powders) and metals are most commonly used as construction materials.

To talk about the possibilities of bioprinting, it is worth mentioning that it is divided into direct and indirect bioprinting. Direct 3D bioprinting is a form of additive manufacturing that uses cells or cells and biocompatible materials as ink, also known as bio-inks. This method can be used to create tissue-like structures layer by layer, which are later used in various fields of medicine and tissue engineering.

In indirect bioprinting, the material being printed from must be a biomaterial (whether it is a polymer, metal, or ceramic). The effects of such a process are the so-called scaffolds as well as implants (both biodegradable and permanent), which are mainly used in hard tissue surgery, e.g. dentistry and orthopaedics.

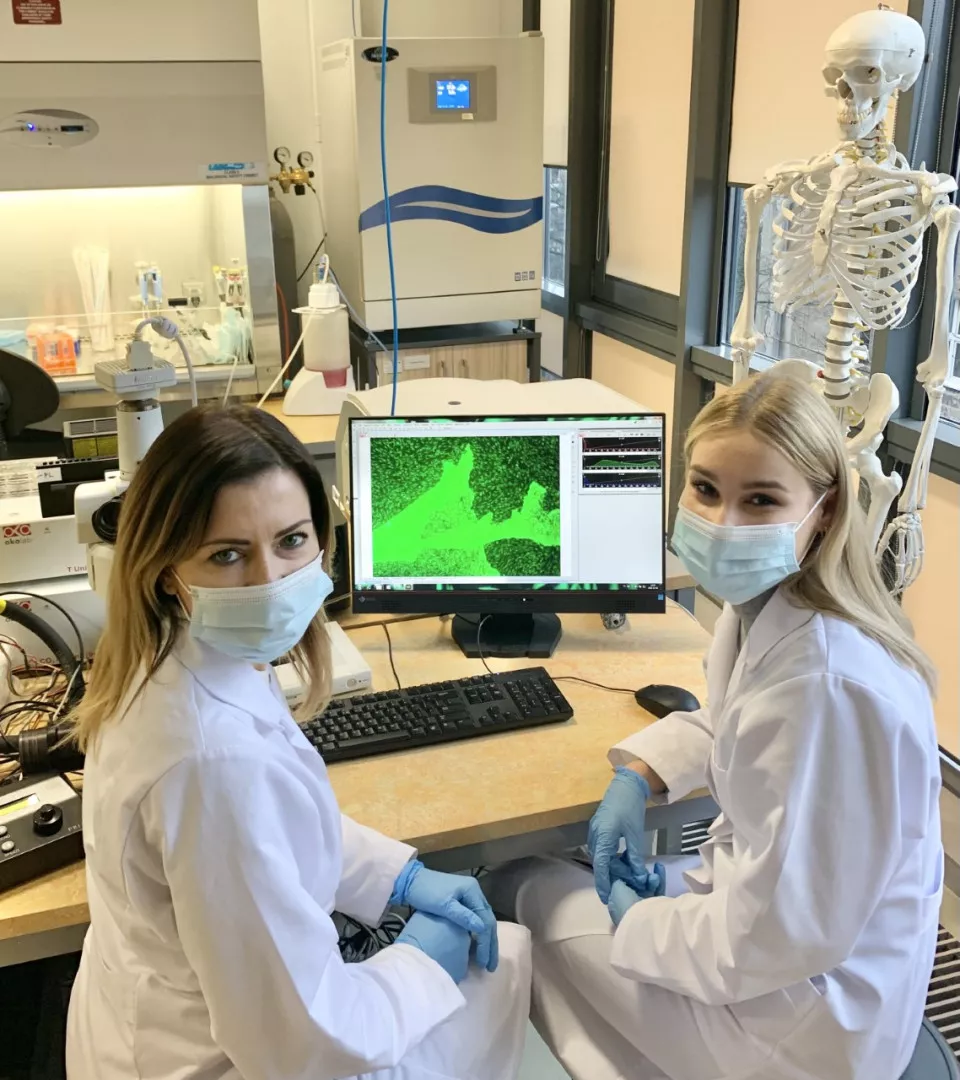

In addition, bioprinting also enables a significant reduction in the number of animal experiments and has applications in the creation of in vitro models for drug and cosmetic testing, as well as in toxicology. 3D printing with living cells is also used to create better models for cancer research. Using 3D printing, incredibly realistic laboratory models of human cancers can be created. Cells can grow, exchange signals with other cell types, and form typical features of real tumours, which is impossible when grown in a flat plastic dish that has nothing to do with the complex architectural development and constant feedback with other tissues that takes place in a living body.

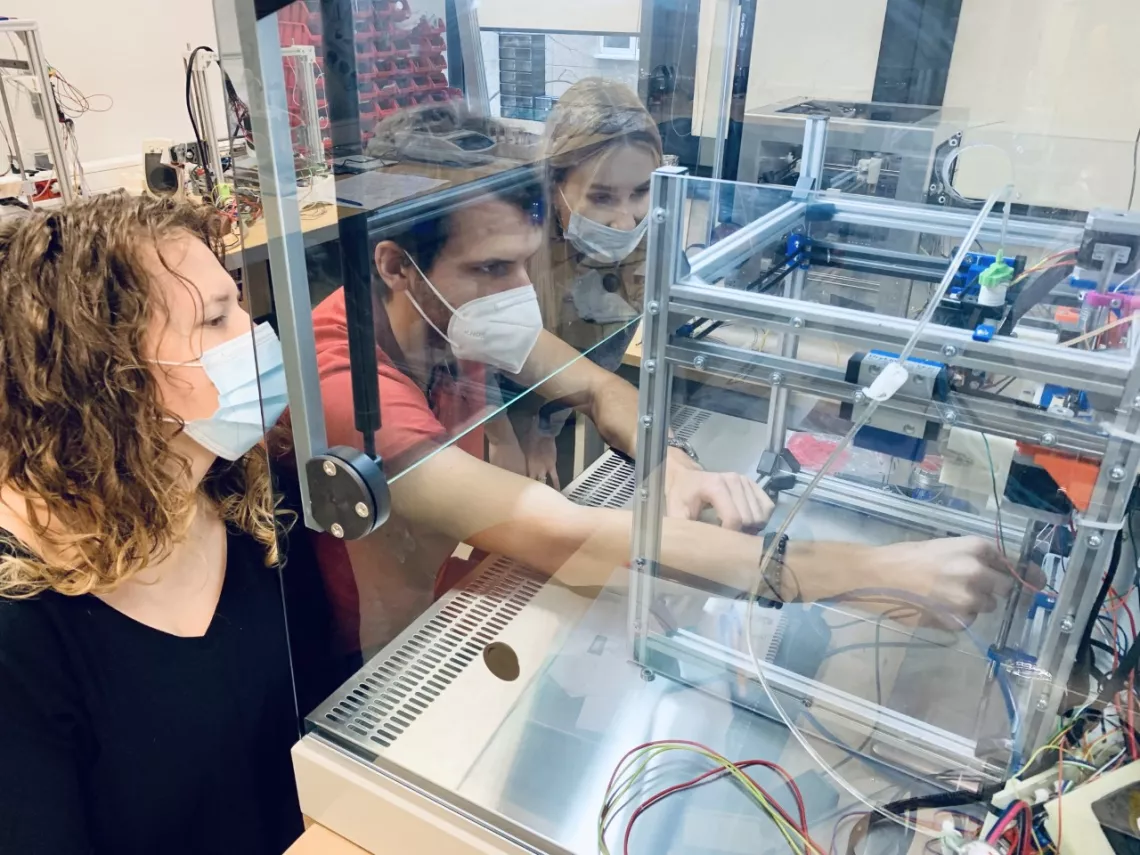

Although 3D bioprinting is already significantly aiding medicine and research, it is mainly associated with printing organs. In this regard, great progress is being made in laboratories around the world, but printed organs are still a matter of time - 20-25 years for functional units and 10-15 years for skin, bone and cartilage. Therefore, all research on materials and printing techniques is still valuable. For this reason, the research of the 3D Bioprinting and Biomaterials Research Laboratory at the Institute of Materials Science and Engineering is focused on the development of biomaterials for bioprinting and the construction of special bioprinters that enable the fabrication of biocompatible scaffolds for biomedical applications by both indirect and direct bioprinting with a certain accuracy and the required mechanical properties from a specific type of material.